In the global energy and industrial sectors, the safe and environmentally compliant storage of coal is a critical link in enterprise operations. Facing increasingly stringent environmental requirements and cost control pressures, traditional storage methods are no longer sufficient. Using steel structure prefabricated buildings to construct professional coal storage warehouses has become the most favored solution today, thanks to advantages such as large spans, fast construction, and long service life. So, how can we design a truly cost-effective modern coal shed?

Precise design is the core of cost control.

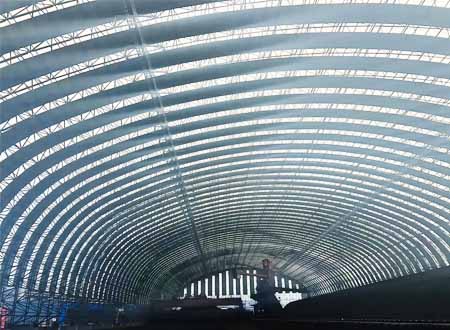

Due to their special functional requirements, coal storage buildings typically demand extremely large covered areas to accommodate stockpiles and equipment operations. For this reason, modern coal sheds generally adopt large-span space grid structures (such as space frames, lattice shells, etc.) rather than conventional portal steel frames. This type of structural system can achieve spans of over 100 meters while ensuring structural safety, with no internal columns required — delivering extremely high space utilization and effectively reducing steel consumption per unit volume as well as overall construction costs. During design, precise calculation of dead loads, wind loads, snow loads, and other forces, combined with rational optimization of member arrangement, is essential to achieve cost efficiency from the very beginning.

Selecting superior materials and efficient prefabrication ensures long-term value.

The main structure uses high-strength steel combined with hot-dip galvanizing or high-performance anti-corrosion coating processes, significantly improving durability in harsh environments such as high temperatures and heavy dust, resulting in substantially lower full-life-cycle maintenance costs. At the same time, prefabricated production is key to controlling both cost and construction schedule. All steel components are manufactured in the factory with standardization and mass precision production, ensuring stable and reliable quality. On-site construction is mainly assembly-based, greatly reducing fieldwork time and weather-related disruptions — overall construction costs can be reduced by more than 20%.

Integrating environmental protection technologies for sustainable operation.

Modern coal shed design must incorporate advanced environmental solutions, such as dust suppression systems (intelligent misting), ventilation flow guidance design, and photovoltaic-integrated roofing, among others. These features not only help meet strict environmental standards and avoid potential fines, but also continuously reduce operating costs through energy saving, consumption reduction, and energy recovery — ultimately improving the project’s overall economic performance.

In the professional field, Henan Gefan Building Materials Co., Ltd. — as a manufacturer specializing in steel structure prefabricated buildings — deeply understands the unique requirements of coal storage. The company is committed to providing global clients with customized solutions, including large-scale coal sheds, warehouses, and other industrial buildings. With excellent engineering execution capabilities and reliable product quality, it ensures every project is completed efficiently within budget, helping clients achieve the optimal balance between storage safety and investment return.

In summary, an economically efficient coal storage building relies on the precise design of large-span spatial structures, high-quality prefabricated manufacturing, and the integrated application of environmental protection technologies. Choosing a partner with professional experience and strong technical capabilities is the key to successfully creating a coal storage facility that excels in both performance and cost.