steel roof design

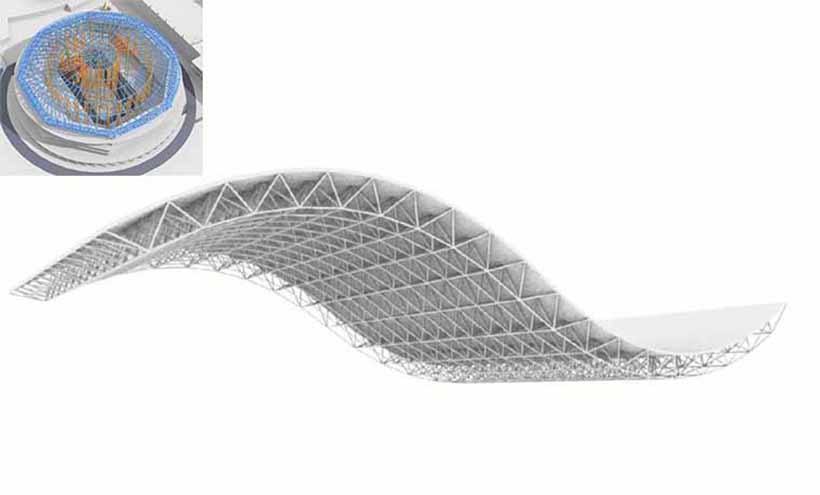

The design of a steel roof should be based on the specific project application, taking into account factors such as structural strength, waterproof performance, and thermal insulation. Prefabricated steel structures are often used as the load-bearing components of steel roofs. Depending on the span and spatial requirements, an appropriate structural form should be selected. For large-span metal roofs, a grid-truss structure is recommended due to its high structural strength and suitability for long-distance transportation.

Henan Gefan Building Materials Co., Ltd. adopts BIM modeling technology to closely integrate prefabricated steel structures with metal roofing systems, improving model accuracy and reducing construction costs.