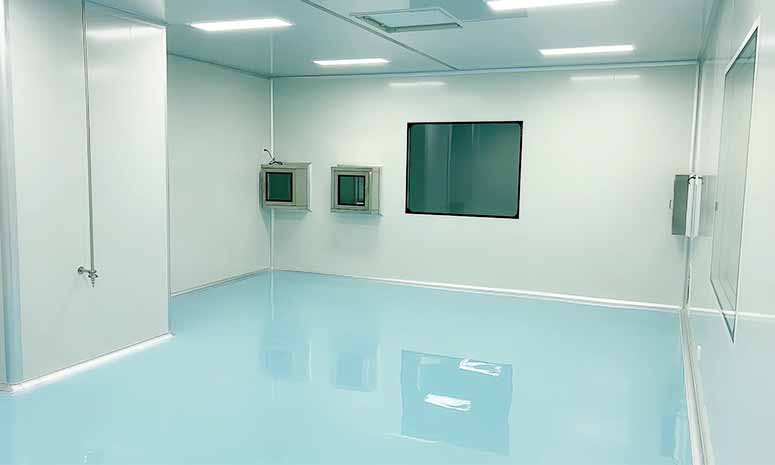

Clean Room

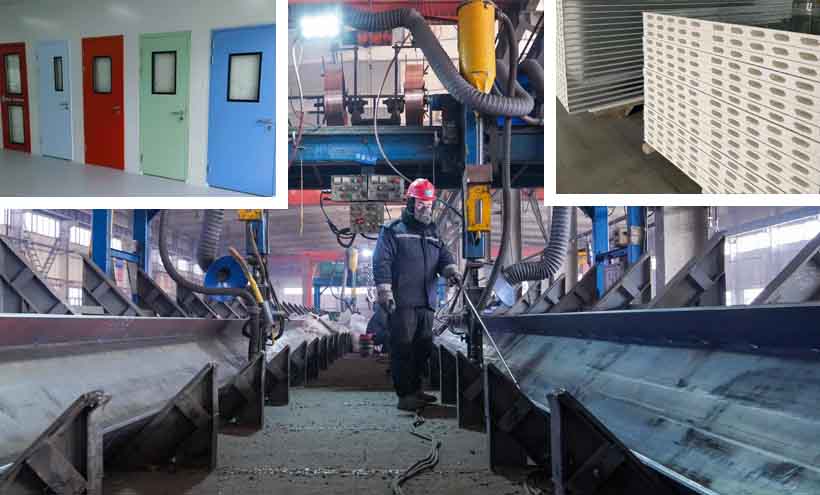

A Clean Room is a critical facility in modern manufacturing, ensuring product quality and safety. It is widely used in high-standard manufacturing sectors such as electronics, pharmaceuticals, food, and medical devices. As a professional prefabricated steel building and clean room manufacturer, Henan Gefan Building Materials Co., Ltd. provides global clients with integrated, one-stop services encompassing design, manufacturing, logistics, and on-site installation.

Building Height:12m – 40m

Steel Grade:Q235B, Q355B, ASTM A36, Stainless Steel

Cleanliness Class: ISO 1 to ISO 10