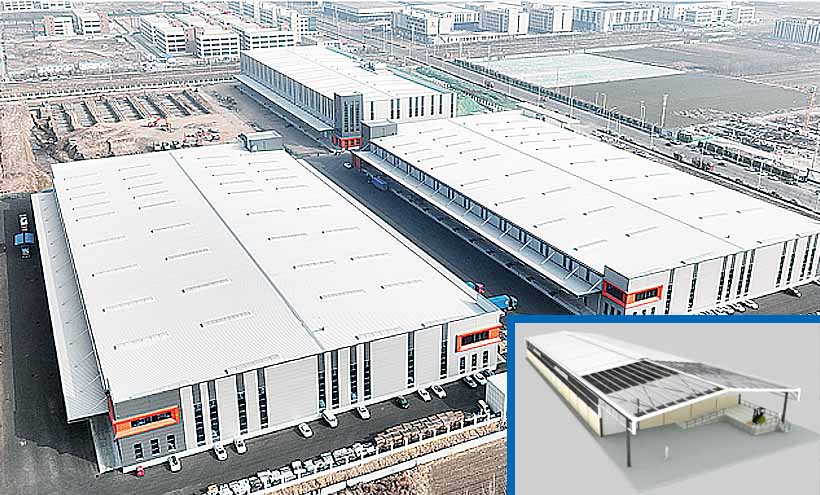

Scientific Functional Zoning and Customized Layout.

The functional zones of a winery typically include the grape receiving area, fermentation hall, aging cellar/warehouse, bottling and packaging workshop, and finished goods warehouse. Rational process flow and zoning are crucial for enhancing production efficiency and management standards. Our company can develop customized design solutions based on your site configuration and local environmental factors (such as climate and geology). The solutions will comprehensively evaluate the corrosion resistance and structural durability of the steel structure system, with special consideration given to the insulation, thermal isolation, and ventilation requirements of key areas like the fermentation zone and cellars. The design can also be integrated with internal storage racking systems to ensure smooth and efficient logistics and management flow throughout the entire facility.

High-Standard Corrosion Protection and Precision Manufacturing.

The wine production environment often involves high humidity, placing extremely demanding requirements on the corrosion resistance of the steel structure building. To address this, we primarily use hot-dip galvanized steel as the main structural material and can apply high-performance anti-corrosion coatings (such as epoxy zinc-rich primer, polyurethane topcoat) to critical areas, significantly enhancing the building's durability and corrosion resistance. Through rigorous structural mechanical calculations and load analysis, we ensure that the strength and stability of all steel components (such as steel beams, columns, purlins, and bracings) fully comply with codes and bearing capacity requirements. During the production phase, we employ BIM 3D information modeling for full-process control and utilize advanced techniques like laser cutting, CNC drilling, and automated welding for raw material processing, ensuring the highest standards of dimensional accuracy and welding quality for all components.

Prefabrication and Lean Logistics.

All steel components undergo prefabricated production within the factory. Before shipment, each component is marked with a unique identification code to ensure efficient and precise on-site installation. The superior anti-corrosion coatings demand high standards of packing protection. We use specialized packaging materials (e.g., PE film, anti-rust paper) and custom wooden crates/pallets to prevent coating damage from friction or impact during transit. Prior to shipment, our company conducts professional 3D container loading simulations and transportation scheme optimization to maximize container space utilization, effectively reducing logistics costs and transportation risks.