Lightweight Steel Structure Building Production

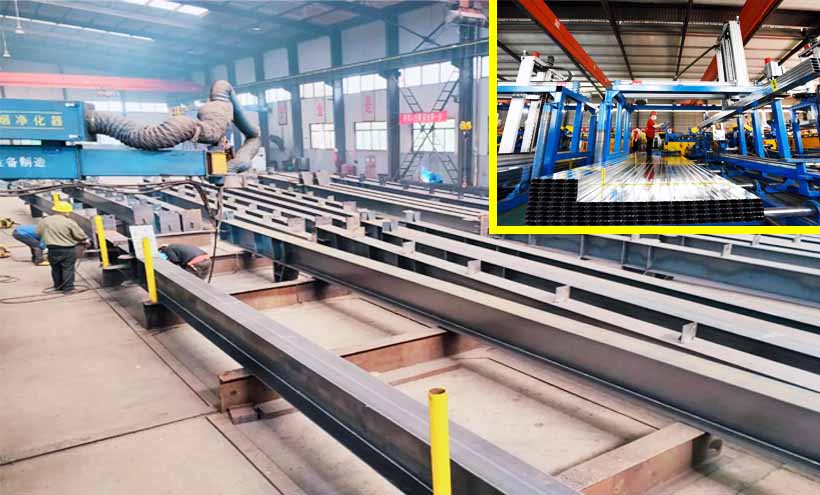

The manufacturing process starts with procurement of raw materials compliant with international standards, with each batch of steel accompanied by third-party inspection certificates. Automated production lines are equipped with Computer Numerical Control (CNC) cutting systems and robotic welding workstations, ensuring component machining accuracy within ±1.5 mm. The quality control system includes welding procedure qualification, non-destructive testing, and dimensional verification, with all critical connection nodes confirmed via digital scanning. Surface treatment employs automated shot blasting and spraying equipment, with coating thickness monitored and recorded in real-time using electronic thickness gauges.