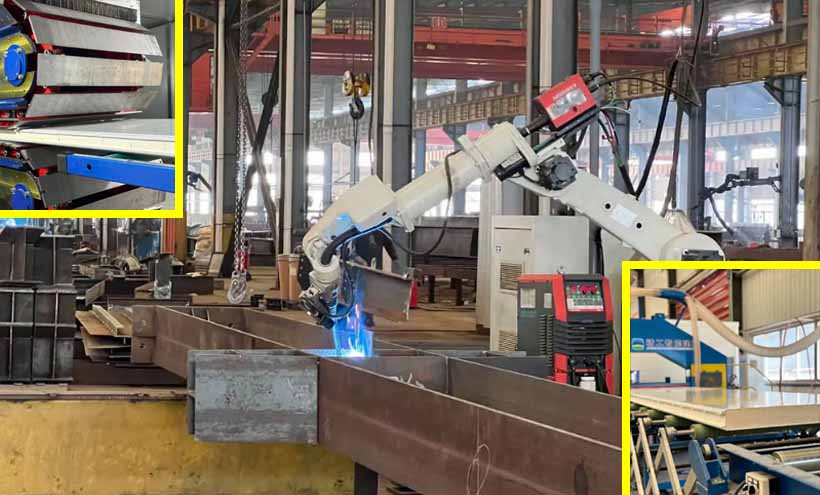

The design of refrigerated vegetable storage involves three key considerations. First, the layout design must account for areas such as pre-cooling, processing, packaging, storage, the refrigeration equipment room, and logistics pathways. A well-planned layout is the foundational step in vegetable cold storage construction. Second, the cold storage structure utilizes a prefabricated steel framework, with steel components connected using high-strength bolts, enabling rapid commissioning and a quicker return on investment. Third, the selection of refrigeration equipment is based on the temperature requirements and storage volume of the goods, ensuring precise control of temperature and humidity inside the cold room.

Henan Gefan Building Materials Co., Ltd. specializes in the construction of modular vegetable cold storage units, seamlessly integrating prefabricated steel structures with refrigeration systems. By employing BIM modeling, we enhance the quality of the cold storage while reducing construction costs.