We focus on heavy steel structure workshop, Provide safe, durable, and cost-effective solutions. With strong expertise in steel structure design and engineering, our team delivers customized layouts that ensure fast installation, reliable crane operation, and long-term durability.

As a professional supplier of prefabricated steel buildings and steel workshops, we focus on safety, energy efficiency, and cost savings, helping clients worldwide build large-span industrial facilities with confidence.

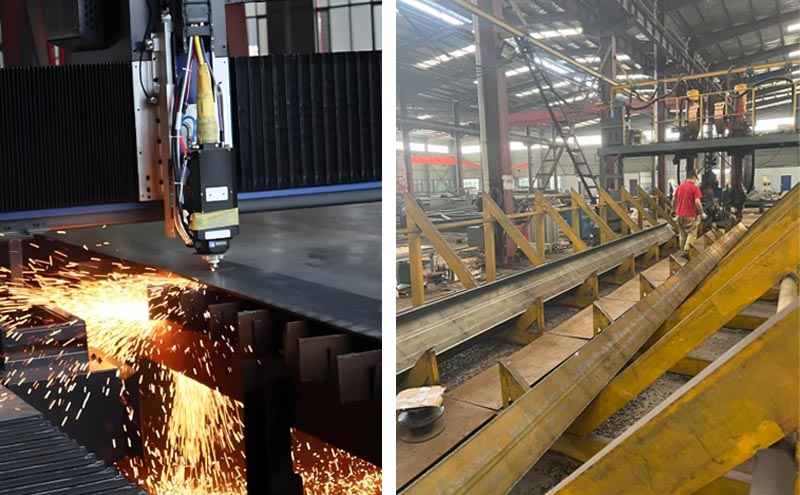

Advanced laser cutting equipment is employed to guarantee material dimensional accuracy and enhance installation efficiency.

Modern automated welding systems are utilized to optimize component production processes, enabling self-sufficient manufacturing of all structural parts.

Multi-layer anti-corrosion coatings are applied to significantly extend the structure's service life.